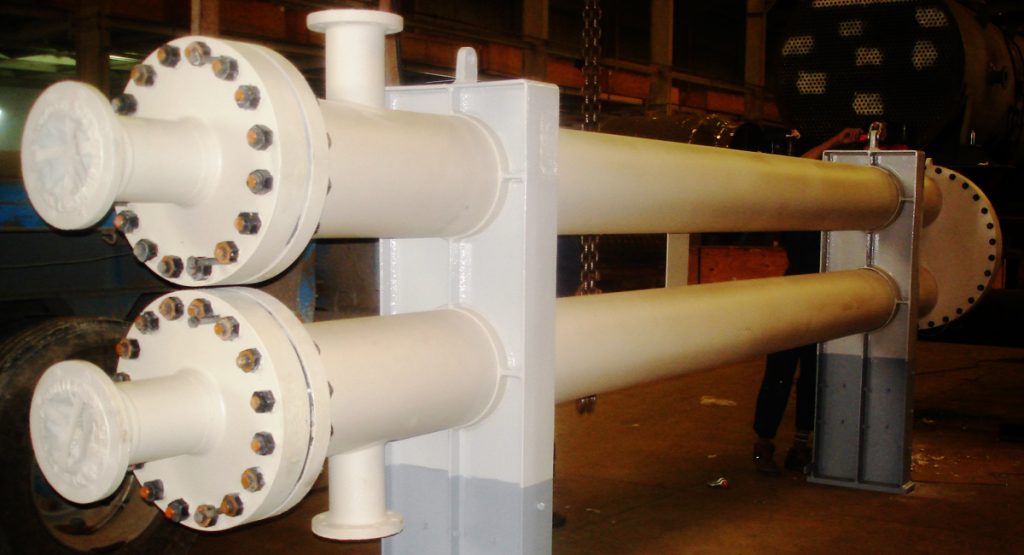

Shell & Tube Heat Exchangers

DOLPHIN carries out Mechanical Design and detailed fabrication drawings of Shell and Tube Heat Exchangers in UAE as per ASME Sec.VIII Div.I & TEMA. We use mechanical design software, which produce complex designs for various operating conditions and come up with most optimum solutions.

All fabrication drawings are generated on drawing software.

Fabrication facilities include CNC Drilling (for Tube Sheet Drilling), Orbital Welding Machine (for Tube to Tube Sheet Welding) & Microprocessor based Telescopic Expansion Machine ( for Tube to Tube Sheet Expansion) in addition to the regular machines like Plate Bending, TIG / ARC Welding, Grinding, Plasma Cutting etc. A full range of vertical and horizontally mounted heat exchangers is used in industries ranging from Chemical Plants and Paper Mills to Oil Refineries and offshore platforms. Customer’s specific thermal, mechanical and dimensional requirements are met with capacity of upto 400 bar g pressure and temperature of upto 1000ºC supplied with full certification as per TEMA(Class R,C,B) ASME Sec. VIII Div.1, BS, DIN Standards.

Shell and tube heat exchangers are widely used in various industries such as HVAC, chemical processing, oil and gas, and power generation due to their robustness and ability to handle high pressure and temperature differences. They can be configured in different ways, such as counterflow or parallel flow, depending on the application and desired thermal efficiency. Key components include tube sheets, baffles, and tie rods, which guide the fluid flow and maximize heat transfer. The simplicity and scalability of the design make shell and tube heat exchangers an ideal choice for a wide range of industrial heat exchange applications.

- List Item #1

- List Item #3

- List Item #3